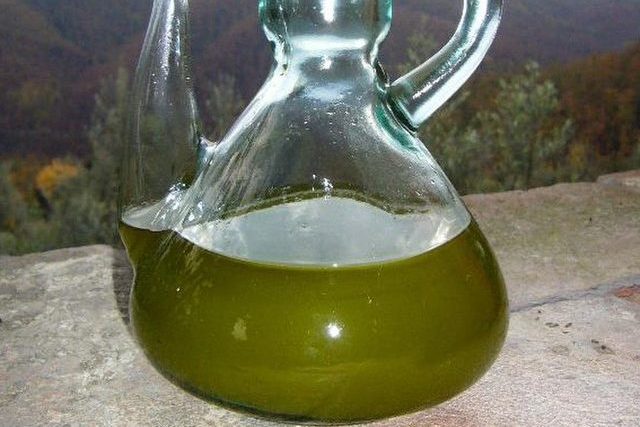

An example of technology to improve the sustainability and competitiveness of Italy’s olive oil sector developed in a recent research project.

Currently, Italy is the third country in the world, after Spain and Tunisia, for olive-growing area of 955,000 ha, but remains the second largest producer in the world with 4,250,192 q of oil (ISTAT, 2022).

Our country holds the richest germplas olive grove comprising over 630 cultivars, with a high presence of local varieties that define specific areas to which they are historically and culturally linked. Italian olive growing is now widespread in all regions, including the Aosta Valley where the first hectare of olive grove has recently been registered (ISTAT, VII Censimento Agricoltura).

Italy has the largest number of certified extra virgin olive oils (42 PDO and 8 PGI), 4 PDO for table olives and 75 Pat-approved olive products (Traditional Agri-Food Products), however, being the world’s leading importer of olive oil, the product bottled as 100% Italian represents less than 30% of total production. These circumstances mean that there are medium-low-end productions, characterized by a limited enhancement of the product.

Olive oil, the problem of fraud

According to EU food fraud control reports, olive oil is one of the goods most affected by fraudulent manipulation. The crisis of recent years has exposed quality production even more to forms of unfair competition, which harms producers and consumers. In the context of the production and sale of extra virgin olive oil, it is mainly dealing with commercial counterfeits, or

- the fraudulent attribution of controlled designations of origin to unrequired goods;

- production and marketing of protected designation of origin (Dop) oils obtained from olives harvested in areas outside the reference area and, more generally, misuse of the marks;

- incorrect labelling in the information provided, with misleading descriptions or not corresponding to the actual characteristics;

- failure or irregular keeping of load-unloading records and non-compliance with the regulations regarding the Sian telematic register.

A second type of fraud that is being seen in the world of extra virgin olive oil is counterfeiting, when one product is replaced by another less valuable one. In recent years, this has often happened as in the case of mixing with lower cost olive oils, coming from non-European countries such as Tunisia or Morocco.

In Italy, given the great popularity of this condiment – we are the first in the world for per capita consumption – and the economic value of the sector, the issue of counterfeit oil is particularly heard.

Traceability tools

For many manufacturers, the use of an automatic traceability system makes it possible to strengthen their quality product with the possibility of giving a complete and safe guarantee of origin and processing of the product in order to obtain the characteristics declared on the label.

The following elements are required to record data and achieve an integrated and intelligent 4.0 Traceability system:

- a series of smart or smart devices (i.e. equipped with one or more sensors and microelectronic components for data acquisition);

- typically wireless (wireless) connectivity;

- the cloudand user access and maintenance software platforms.

These elements are beginning to be available and at a low cost, which is why it is therefore possible to speak of Traceability 4.0 as an expanding sector on the wave of digitization that now pervades our entire environment.

The proposed system

As part of the Olivosmart research contract, the company SISSPre S.r.l. – Sistemi e Servizi di Precisione, with the collaboration of the Crea-OFA of Rende has designed a traceability system called Trust Three for the fully automatic, economical and versatile olive-oil supply chain (also usable on other agri-food supply chains). As part of the project, Crea and SISSPre conducted a series of company-wide trials for the evaluation of the different possible scenarios of the production flow and the business organization starting from the Italian olives’ harvest phase by acquiring the necessary information to be automatically recorded and sent to a secure server where the customer data store is stored. This data is then managed by a platform software capable of numerous processing over time.